Concrete Protection Liner (CPL) Highlights

Concrete Protection Liner Solutions | High-Performance Concrete Protective Liners for Optimal Durability

Engineered Containment’s Concrete Protective Liner (also called Concrete Protection Liner, or CPL for short) is typically made with a high-density polyethylene (HDPE) geomembrane sheet with one side studded to firmly anchor onto applied surfaces. Other options, beyond HDPE, are available depending upon the application. This liner provides excellent protection for concrete structures against corrosion, erosion, and mechanical damage. Offering outstanding long-term durability (with a focus on our 100 year design service life), our Concrete Protective Liner helps extend the lifespan of a wide range of concrete structures, including cast-in-place sewer tunnels, sump pits, liquid storage tanks, digesters, manholes, and more.

-

Offers high chemical resistance. A specific review of the chemical makeup may be required to ensure the correct formula is used for your project.

All Engineered Containment CPL Exhibits high pull-out strength. (ASTM D7853)

When used correctly, it experiences minimal lateral movement from thermal expansion & contraction. Extremely important with variable weather climates like Canada.

Provides exceptional protection against chemical and mechanical damage.

Resistant to UV degradation. (If UV stability is important for your project - specific increased UV-stable formulas are available)

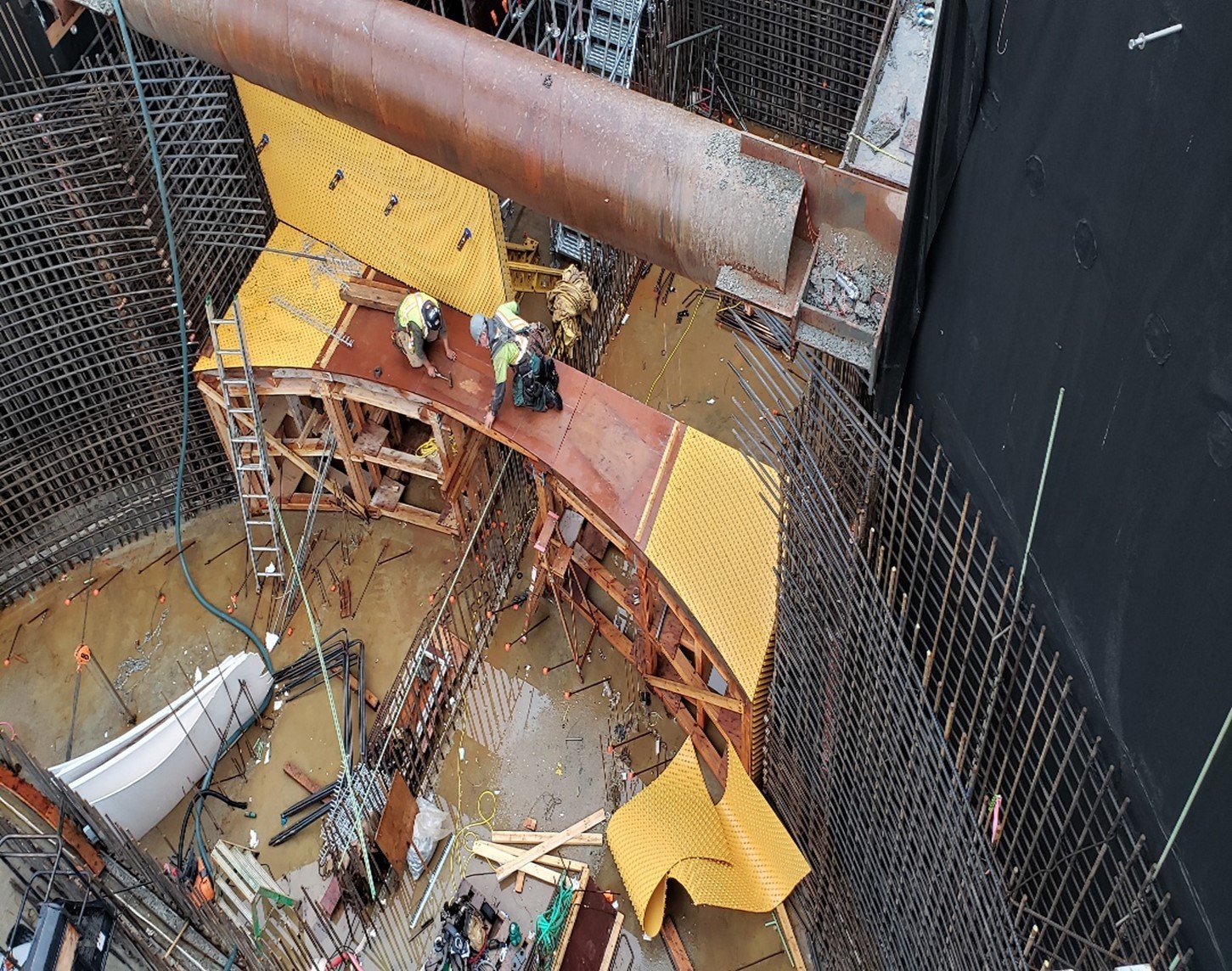

Can be custom-fabricated to specific dimensions or geometric shapes. This is critical for cast-in-place applications such as WWTP digester roofs!

-

Most CPL is made of high density polyethylene (HDPE). However, other formulas are available depending on the specific project requirements - allowing for flexibility. Formula changes to the base resin may be used for high-temperature applications, specific chemical containment and UV exposure.

Most CPL is available in widths up to 2.44m and lengths up to 70m. For large diameter applications, production orders can be made up to 7m widths to reduce the number of welded seams required in an installation.

Engineered Containment offers the option to partner together to achieve a 100 year design service life for all concrete protective liner projects. Please contact us for more information on our 100 design service life initiative.

-

Concrete Sewer Tunnels / Trunk Lines

Concrete Storm and Combi Lines / Trunk Line (Helpful for Abrasion)

Concrete Sump Pumps

Pre-Cast Concrete Manholes / Maintenance Holes

Concrete Processing Pits

Concrete Storage Tanks

Concrete Digesters at Wastewater Treatment Plants

Prefabricated Concrete Structures (Box Culverts, etc.)

Concrete Potable Water Storage (NSF 61 Version Available)