FABRICATED Liners

With standard lead times of only 2-5 business days, Engineered Containment is able to provide all your prefabricated liner needs. Fabricated liners are the ideal solution for smaller jobs, where field fabrication is not required. Our team is happy to provide answers regarding the suitability of these liners for your unique job/application.

Engineered Containment is “THE” organization for small client-installed liners. The success is based on our 100% seam and liner pass rate given the additional QA/QC we complete versus other liner manufacturers as well as our ability to quickly manufacture and deliver to our customers in the demanding and fast-paced oil & gas and petrochemical industries.

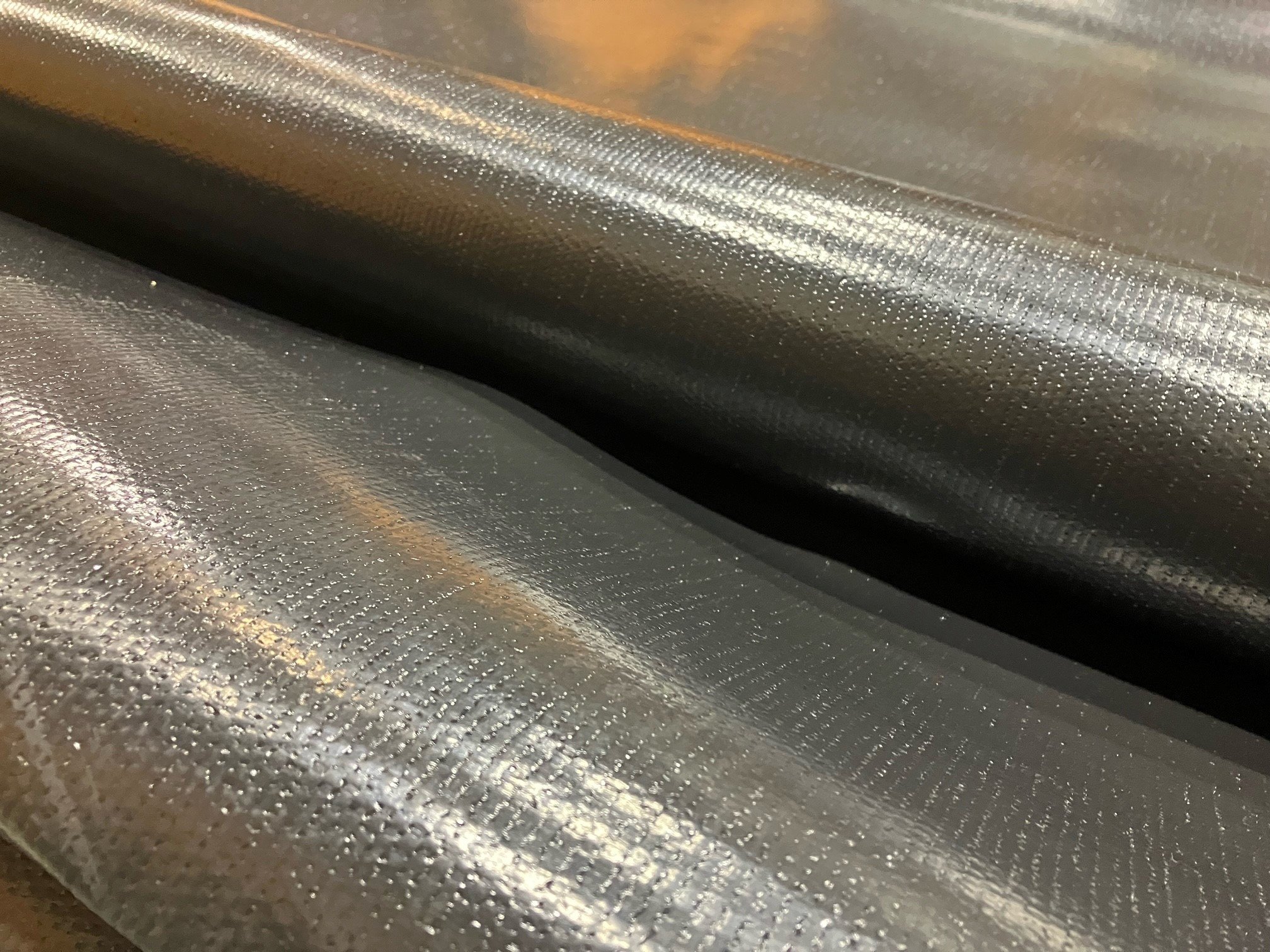

Material Options:

Linear Low-Density Polyethylene (LLDPE) - 30mil

Tape-Reinforced Woven Polyethylen (TRWP) - 20mil, 24mil, 30mil

Size availability:

Maximum Length = 100’

Maximum Width = 240’ (sizing options available in 12’ increments)

Larger sizes may be available upon special request, but would not fall into standard lead times.

Other Fabricated Products

turbidity curtains

Floating Turbidity Curtains (also known as floating turbidity barriers or floating silt curtains) are "in-water silt fences" that are designed to restrict or prevent the migration of suspended sediments in a body of water.

Containment Berms

Spill containment berms, or containment berms for short are portable or fixed barriers used to contain spills or leaks of hazardous substances. These containment systems are essential in industries such as oil and gas, chemical manufacturing, and transportation, where the risk of spills is high. They are designed to prevent the spread of hazardous materials, protecting both the environment and the safety of workers.

Asset protection & tarps

Equipment and people are the key assets of any operation (refinery, manufacturing facility, or construction site). Engineered Containment provides complete E-Tuf™ tarp systems to protect people, equipment and materials from the harshest weather our environment has to offer. ECI’s proprietary Visual and Visual/Sound Barrier Tarping Systems for commercial or construction site fences provide security and privacy.

silt bags/silt socks

Silt Bags are designed to filter water as it is pumped from a storage or construction site, removing hazardous materials such as silt before it damages the environment and the storm water system.