Thermal Plastic (Thermoplastic) Concrete Protection Liner

At Engineered Containment, we provide advanced Thermal Plastic Concrete Protection Liners (Thermoplastic) designed to safeguard concrete structures from harsh chemical environments, moisture, and physical wear. These liners offer a durable, long-lasting solution for critical infrastructure, ensuring both performance and longevity in various industrial, municipal, and commercial applications.

What is a Thermal Plastic Concrete Protection Liner?

A Thermal Plastic (thermoplastic) Concrete Protection Liner is a highly durable barrier made from thermoplastic materials, specifically engineered to protect concrete surfaces from corrosive chemicals, water, and environmental degradation. These liners are essential in environments like sewage treatment plants, chemical storage facilities, or industrial piping systems, where traditional concrete can be compromised by harsh conditions.

Polyethylene (PE, or HDPE) is the most commonly used thermoplastic for these liners due to its excellent chemical resistance, flexibility, and durability, making it ideal for large-scale infrastructure protection.

While Polyvinyl Chloride (PVC) has historically been used in various applications, it is now falling out of favor in many industries due to environmental concerns during production and disposal. Polypropylene (PP), on the other hand, continues to be used in some high-temperature applications where its heat resistance is beneficial. However, despite its specific advantages, PP lacks the versatility and chemical resistance of Polyethylene (PE), which remains the most commonly used material for thermal plastic liners in concrete protection.

For specialized applications, Polytetrafluoroethylene (PTFE), commonly known as Teflon, is utilized because of its superior resistance to extreme chemicals and high temperatures. However, due to its cost and specific properties, PTFE is reserved for niche applications in extreme environments.

Other thermoplastics like Acrylic, Polycarbonate, and Nylon are generally not used for concrete protection liners due to their mechanical properties being less suitable for the harsh conditions typically encountered in industrial environments.

Key Benefits:

Chemical Resistance: Thermoplastic liners provide exceptional protection against a wide range of aggressive chemicals, including acids, alkalis, and solvents, preventing corrosion and degradation of the underlying concrete.

Moisture Barrier: These liners act as a waterproof barrier, protecting concrete from prolonged exposure to moisture, which can lead to cracking, spalling, and reduced structural integrity.

Thermal Protection: Thermoplastic liners offer excellent resistance to temperature fluctuations, helping to maintain structural integrity in both high-temperature and freezing conditions.

Long-Term Durability: By preventing chemical and moisture infiltration, these liners extend the lifespan of concrete structures, reducing maintenance and repair costs over time.

Applications of Thermal Plastic Concrete Protection Liners

Our Thermal Plastic Liners are widely used in a variety of sectors where concrete structures require enhanced protection, including:

Sewage and Wastewater Systems:

Protect manholes, pipelines, and treatment facilities from corrosive gases and liquids commonly found in wastewater environments.

Industrial Plants:

Ideal for chemical processing plants where tanks, pipes, and other infrastructure are exposed to highly aggressive chemicals.

Water and Wastewater Treatment Facilities:

Shield concrete structures from chemical exposure during the treatment process, ensuring the longevity of tanks, reservoirs, and containment structures.

Stormwater Management:

Provide a robust barrier in stormwater culverts, tunnels, and retention systems, protecting against water infiltration and chemical runoff.

Our Services

At Engineered Containment, we offer a full suite of services to ensure your Thermal Plastic Concrete Protection Liner is properly designed, installed, and maintained:

1. Design Support

We work closely with engineers to integrate thermal plastic liners into concrete structures during the design phase. Our experts help specify the appropriate liner materials and configurations to ensure optimal performance based on the specific environmental conditions.

2. Liner Supply and Fabrication

We provide top-grade thermal plastic liners, custom fabricated to fit the unique dimensions of your project. This includes pre-fabricating liner sections to simplify installation and ensure a perfect fit for complex structures like pipes, vaults, and manholes.

Common CPL Products in North America Include:

CPL Products No Longer Available (Companies Have Been Dissolved):

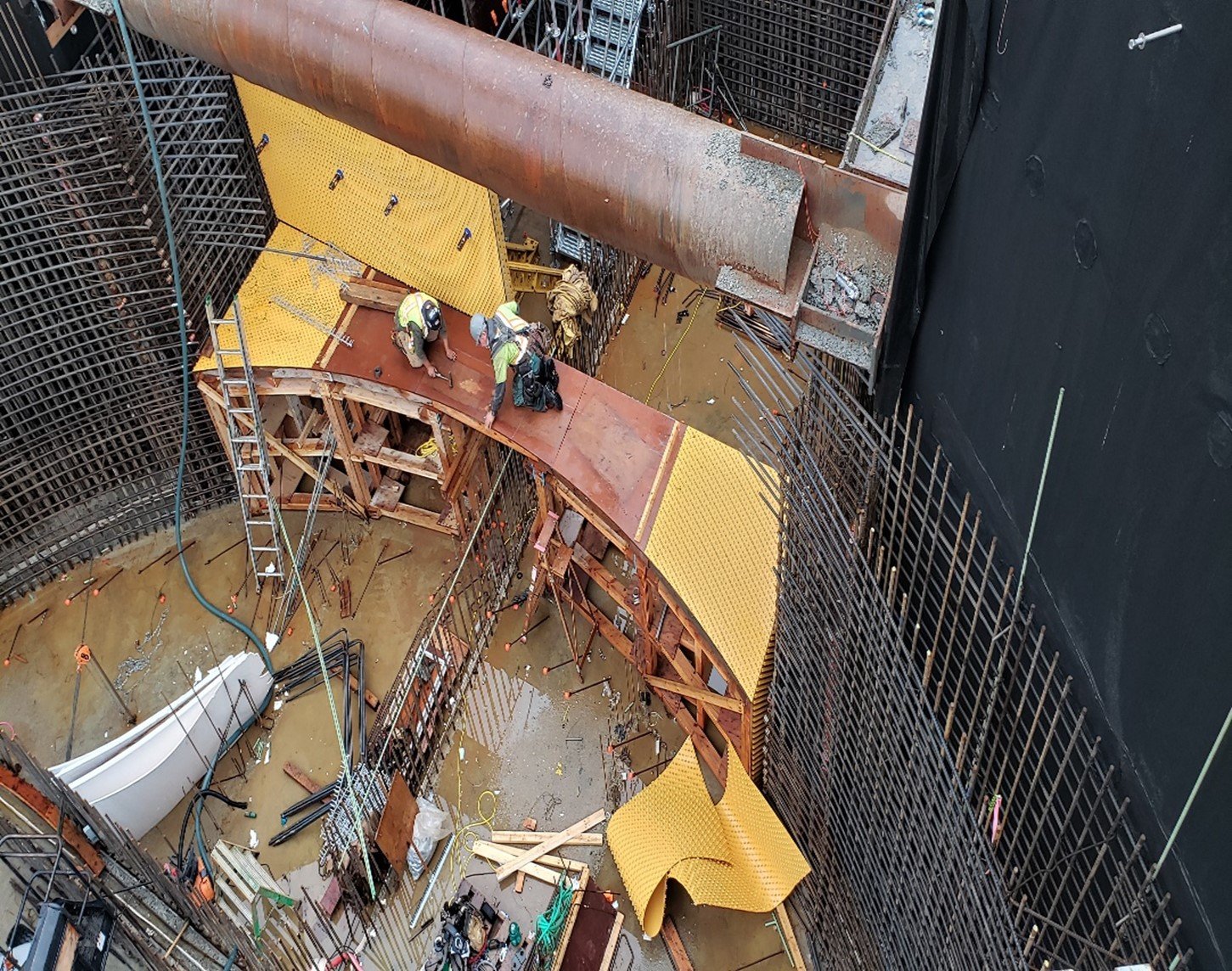

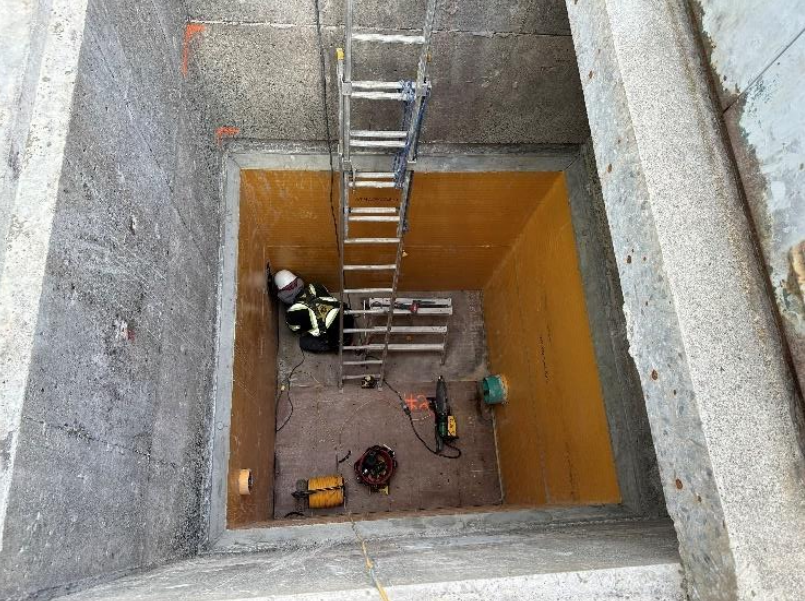

3. Field Installation and Welding

Our field teams are equipped to handle all aspects of liner installation, including welding and sealing to ensure a continuous, impermeable barrier. We work alongside contractors to ensure proper application, whether in new construction or retrofitting existing structures.

4. Inspection and QA/QC Services

We offer comprehensive quality assurance and inspection services to ensure that your liner system is installed correctly and functioning as intended. This includes rigorous testing for leaks, seam integrity, and overall system performance.

Why Choose Engineered Containment?

Expertise: With decades of experience in protective liner systems, we are industry leaders in delivering tailored solutions for concrete protection.

Comprehensive Solutions: From design support to fabrication, installation, and inspection, we offer a full range of services to ensure the successful implementation of your thermal plastic liner system.

High-Quality Materials: Our liners are made from premium thermoplastics, providing superior resistance to chemicals, moisture, and temperature fluctuations.

Client Collaboration: We work closely with engineers, contractors, and facility owners to provide a seamless installation process that meets all project requirements.

Contact Us

For more information on how Engineered Containment can assist with your Thermal Plastic Concrete Protection Liner needs, contact us today. Our expert team is ready to help design and implement a solution that ensures your concrete structures remain protected and durable for years to come.