Top 7 Reasons to Use Concrete Protective Liner (CPL)

Incorporating concrete protective liner (CPL) in a project, as opposed to using unprotected concrete, brings a multitude of benefits that can significantly enhance the longevity, durability, and overall performance of concrete structures. Here are the top 7 benefits of using CPL:

What is Extrusion Welding?

Our methodology is deeply rooted in cutting-edge techniques and compliance with the highest industry standards, notably through the utilization of extrusion welding, a cornerstone in our installation and maintenance services for CPL. Our unwavering commitment to quality assurance and control (QA/QC) aligns with the stringent standards set by the International Association of Geosynthetic Installers (IAGI), among other authoritative bodies, ensuring that our projects set benchmarks in durability and reliability.

PVC vs. HDPE CPL - Which is Best?

In the world of construction and environmental protection, selecting the right materials for concrete protective liners (CPL) is pivotal. Two prominent contenders in this arena are Polyvinyl Chloride (PVC) and High-Density Polyethylene (HDPE). While both materials offer their unique advantages, HDPE often stands out as the superior choice for several compelling reasons, especially when durability, flexibility, and environmental compatibility are paramount.

What is the ASTM D7853 Test?

The ASTM D7853 test method is a crucial procedure for determining the hydraulic pullout resistance of geomembranes with locking extensions when embedded in concrete. It measures the maximum pressure required to dislodge these extensions from the concrete, thereby assessing the liner's anchorage strength. This evaluation is essential for ensuring the durability and effectiveness of protective liners in managing hydraulic pressures in environmental and infrastructure projects, providing engineers with vital data for material selection and design optimization.

100-Year Design Service Life of CPL Lined Concrete Systems

Explore how high-quality Concrete Protective Liners (CPL) ensure long-term durability for infrastructure projects, with tips on selection, installation, and maintenance for a 100-year design service life

New CSA A257 Series:24 Standards and ASTM D7853 Testing

One of the most notable changes is the incorporation of ASTM D7853 testing methods into the CSA A257 standards. This integration signifies a move towards more advanced and reliable testing methodologies for concrete protective liners used in lined concrete structures. The ASTM D7853 standard outlines the hydraulic pullout resistance of a geomembrane with locking extensions embedded in concrete, providing a more accurate measure of the protective liner's effectiveness.

Epoxy Coatings vs. CPL for Concrete Protection

The choice between epoxy coatings and CPL should be based on several factors, including specific environmental conditions, expected wear and tear, chemical exposure, and budget constraints. Here are the key differences to consider:

What is Microbial Induced Corrosion (MIC)?

Concrete Protective Liner (CPL) offers an effective solution to prevent MIC in concrete structures. By creating a physical barrier between the concrete surface and the external environment, CPL shields the concrete from direct exposure to harmful bacteria and their acidic byproducts. This barrier prevents the bacteria from adhering to and penetrating the concrete surface, significantly reducing the risk of MIC.

What is Concrete Protective Liner?

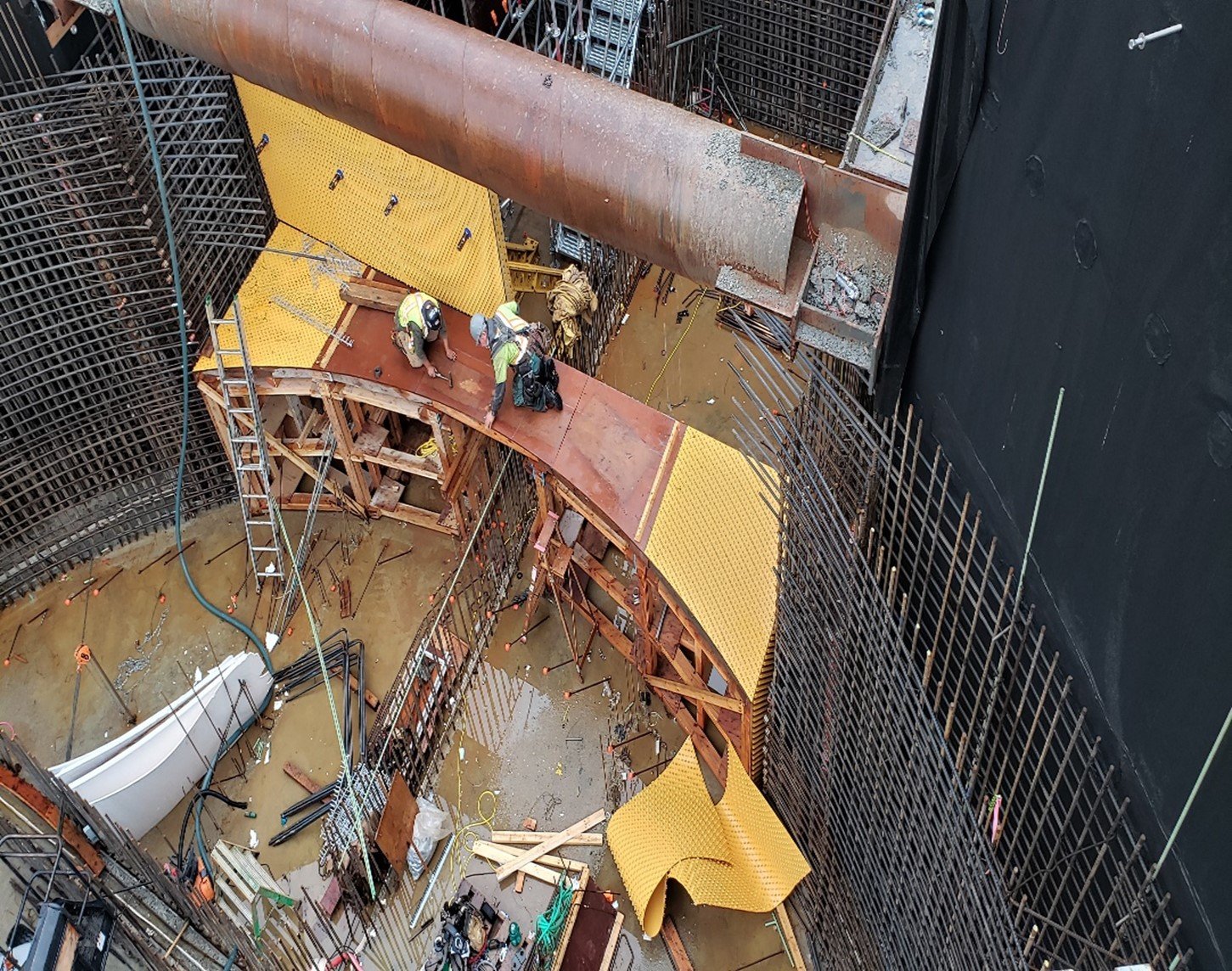

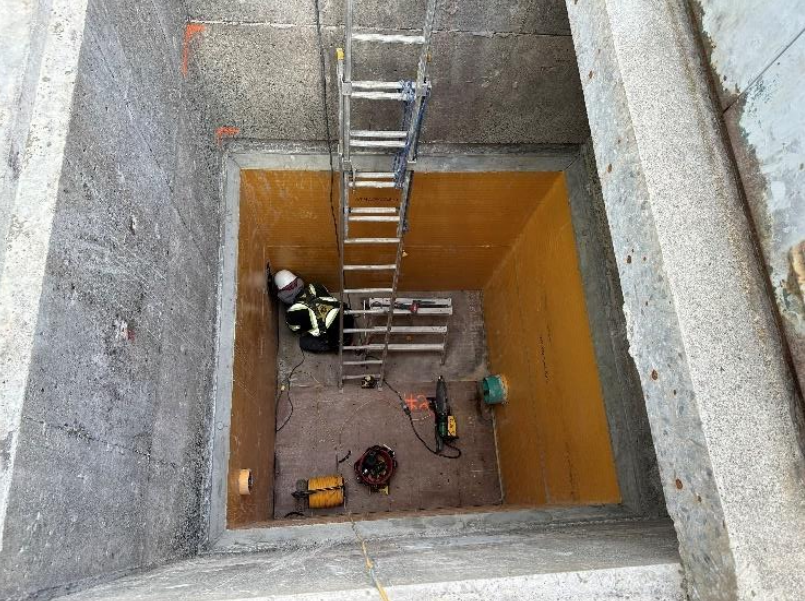

Concrete Protective Liner, also known as concrete protection liner and typically abbreviated as CPL, is a high-quality, durable geomembrane or plastic sheeting that is attached to the interior of concrete structures. This liner acts as a protective barrier, shielding the concrete from chemical erosion (including microbial-induced corrosion (MIC)), physical abrasion, and environmental factors