Microtunneling for Sanitary Applications

Enhancing Durability with Concrete Protective Liners

Microtunneling has become a preferred method for installing underground pipelines, particularly in urban settings where minimizing surface disruption is essential. This trenchless technology is especially effective for sanitary applications, enabling precise installation of jacking pipes under roads, railways, and other existing infrastructure. For projects requiring enhanced protection against corrosive environments, integrating concrete protective liners into jacking pipes offers a robust solution. Engineered Containment plays a vital role in this process, providing advanced liners and specialized welding services within trunklines to ensure long-lasting durability and performance.

The Role of Concrete Protective Liners in Microtunneling

Concrete protective liners are essential in sanitary applications, where pipelines are exposed to aggressive chemicals and wastewater that can significantly impact their integrity. By lining jacking pipes with these specialized liners, we can effectively shield the concrete from deterioration, thereby extending the pipeline's lifespan and reducing maintenance costs.

Engineered Containment collaborates with microtunneling contractors as a specialty subcontractor, focusing on the welding and quality assurance of concrete protective liners. Our certified crews are equipped to perform welding within trunklines with an interior diameter of 900mm or greater, utilizing advanced techniques to ensure seamless installations and enhanced protection. We also work closely with precast producers at the front end, supplying our EC-Fit™ 100 tubes that are cast into jacking pipes before arriving on-site, ensuring an integrated and streamlined installation process.

Challenges in Microtunneling

with Concrete Protective Liners

While microtunneling offers numerous advantages, integrating concrete protective liners in these projects can be more challenging compared to traditional liner applications due to the confined space conditions:

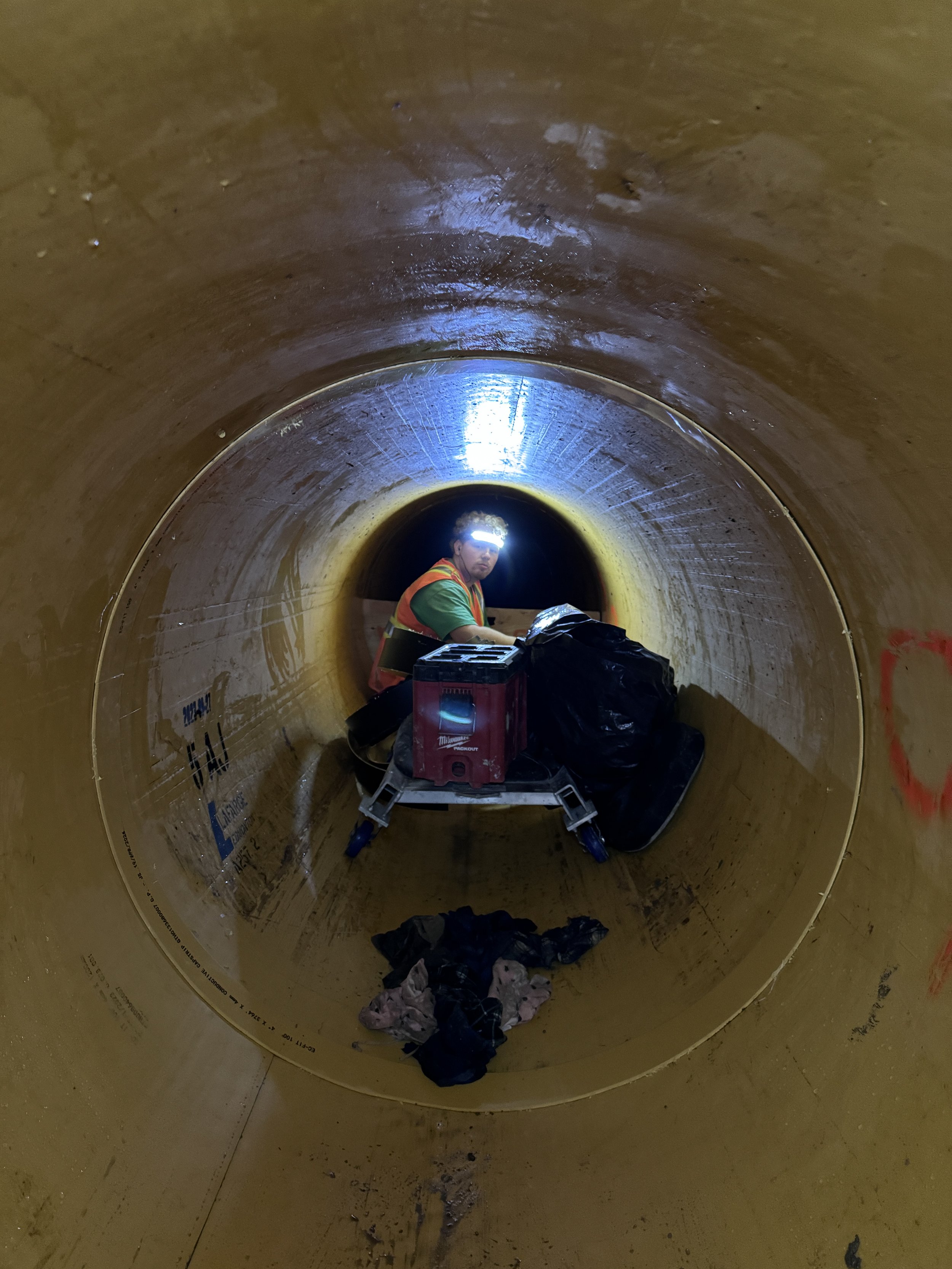

Confined Space Operations: Microtunneling involves working within narrow trunklines, which can restrict access and movement. These conditions require specialized equipment, skilled personnel, and careful planning to ensure precise installation and welding of the protective liners.

Safety Considerations: Confined spaces present heightened safety risks, such as limited ventilation and exposure to hazardous materials. Engineered Containment addresses these challenges by implementing rigorous safety protocols, continuous monitoring, and emergency preparedness measures. Our crews are trained to operate safely and effectively in these environments, prioritizing safety without compromising on quality.

Technical Precision: Installing and welding concrete protective liners within confined trunklines requires meticulous precision to maintain the integrity of the pipeline. Our teams employ advanced welding techniques and thorough QA/QC processes to ensure that every liner is installed correctly, providing robust protection against the harsh conditions found in sanitary applications.

Featured Projects:

Proven Success in Microtunneling Applications

Engineered Containment has demonstrated its expertise in several notable microtunneling projects, showcasing our ability to handle complex confined space installations:

Rangeview Sanitary Trunkline in Calgary: This award-winning project involved the installation of a new sanitary trunkline using microtunneling techniques. By incorporating concrete protective liners into the jacking pipes made by Heidelberg, we ensured the trunkline's resistance to the corrosive conditions typically found in sanitary sewer environments. Our skilled crews performed in-trunkline welding, delivering a seamless installation that meets the highest standards of durability and performance.

West Valley Line Drainage Relocation in Edmonton: As part of the LRT expansion, this project required precision and expertise in microtunneling under existing infrastructure. Engineered Containment provided EC-Fit™ 100 tubes to the precaster, Lafarge Pipe, for use during the manufacturing of the jacking pipes. Our certified crews expertly welded the liners inside the trunkline, ensuring the system's integrity and long-term reliability against corrosive elements.

These are just a few examples of the many projects where Engineered Containment has successfully applied its expertise in microtunneling and concrete protective liners.

Partnering with Leading Brands for Optimal Results

At Engineered Containment, we partner with some of the industry's leading brands to provide the best protective liners for each application. We work with high-quality products like AGRU Suregrip, AGRU Ultragrip, and Solmax Studliner, offering our clients reliable and durable solutions. Additionally, we provide alternatives for now-defunct brands such as KST Holland and Ameron T-Lock, ensuring that our clients always have access to top-performing liners. Our commitment is to continually seek the best products for each job, tailoring our solutions to meet the specific needs of every project.

Comprehensive Services Across Canada, the USA, and Beyond

Engineered Containment proudly offers its specialized concrete protective liner services for microtunneling projects across Canada, the USA, and around the world. Our certified crews are equipped to handle projects of varying complexities, ensuring that each installation meets the rigorous standards required for sanitary applications. From initial consultation to final installation, we provide comprehensive support and technical expertise, making us a trusted partner for clients globally.

Why Choose Engineered Containment?

Choosing Engineered Containment for your microtunneling needs means partnering with a team committed to quality, safety, and innovation. Our certified professionals and use of industry-leading materials ensure that every project is completed to the highest standards. With our capability to weld in trunklines with an interior diameter of 900mm or greater, we offer unparalleled flexibility and expertise in confined space operations.

Whether you're planning a new installation or upgrading existing infrastructure, Engineered Containment has the experience and skills to deliver solutions that stand the test of time. Contact us today to learn more about our microtunneling services and discover how we can help protect your pipeline investments across Canada, the USA, and globally with concrete protective liners.