Improve Infrastructure Safety with Concrete Protection Liners

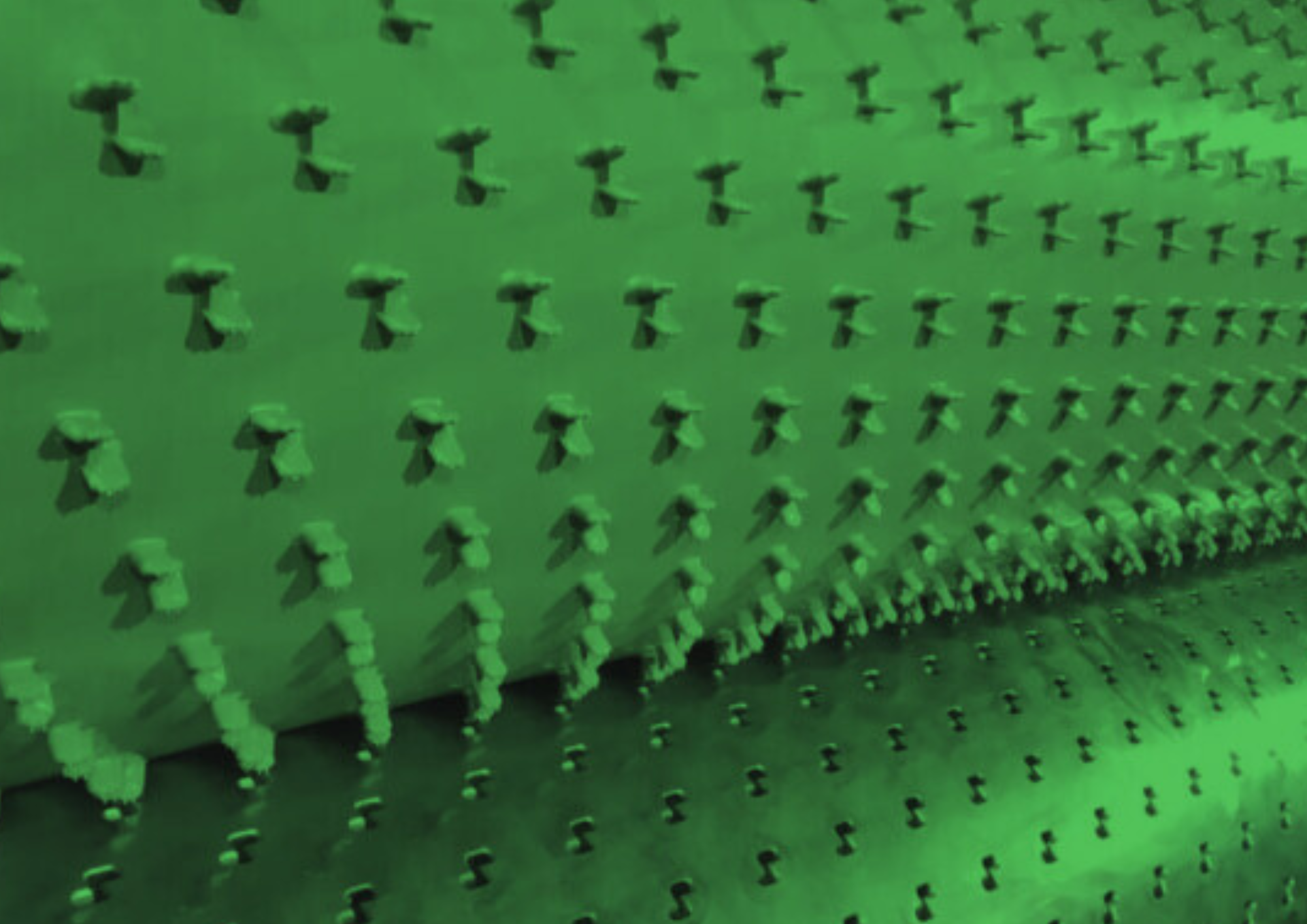

Concrete protection liners play a crucial part in keeping our infrastructure safe and durable. They act as a barrier, protecting concrete from harmful substances like chemicals, wastewater, and other contaminants. By stopping leaks and preventing corrosion, these liners help structures last longer and stay strong.

Using the right type of concrete protection liner is important for different projects. Whether it's for wastewater treatment plants, chemical storage, or stormwater systems, the correct liner ensures the infrastructure stays safe and effective. Moreover, it keeps harmful substances from polluting the environment, making it an essential choice for eco-friendly construction.

Choosing and installing concrete protection liners can be complex, involving careful planning and expert advice. Assessing the project needs, understanding different liner materials, and consulting with professionals all play a part in making the best choice. Getting it right means safer, more sustainable infrastructure that stands the test of time. Let's dive into the different types of liners and how to choose the right one for your needs.

Understanding Different Types of Concrete Protection Liners

Concrete protection liners come in various types, each suited for specific applications and environments. One common type is the polyvinyl chloride (PVC) liner. PVC liners are known for their flexibility and ease of installation. They are often used in applications where the liner needs to conform to complex shapes and surfaces. However, PVC liners can be vulnerable to chemical degradation and may not be suitable for environments with high chemical exposure.

Another popular type is high-density polyethylene (HDPE) liners. HDPE liners are highly resistant to chemicals and UV radiation, making them ideal for harsh environments. They are commonly used in industrial settings and for environmental protection projects. On the downside, HDPE liners are less flexible than PVC and can be challenging to install in intricate configurations. Ethylene propylene diene monomer (EPDM) liners offer excellent weather resistance and flexibility but may be less durable in high-stress applications.

Each type of liner has its pros and cons. PVC liners are user-friendly and versatile but may have limited chemical resistance. HDPE liners are durable and chemical-resistant but less adaptable to complex shapes. EPDM liners provide good flexibility and weather resistance but may not withstand heavy mechanical stress. Choosing the right liner involves understanding these characteristics and matching them to the project's specific needs.

Key Factors to Consider When Choosing a Concrete Protection Liner

Selecting the right concrete protection liner requires careful evaluation of several factors. First, consider the project's requirements and environmental conditions. For instance, a liner for a wastewater treatment facility needs to withstand continuous exposure to various chemicals and liquids. In contrast, a liner for a containment pond must resist UV radiation and weather changes. Understanding these conditions helps in choosing a liner with the appropriate properties.

Chemical resistance and durability are critical factors. The liner must be able to resist the specific chemicals it will encounter to prevent degradation. Durability ensures the liner maintains its protective qualities over time, reducing the need for frequent replacements. Installation process and maintenance are also important. A liner that's easy to install saves time and labour costs, while easy maintenance ensures the liner remains effective without requiring extensive upkeep.

Cost considerations and long-term benefits play a significant role in the decision-making process. While upfront costs are a factor, it's essential to consider the long-term savings from reduced maintenance and longer lifespan. A liner that costs more initially but lasts longer and performs better may be more cost-effective in the long run. Balancing these factors ensures the chosen liner provides the best performance and value for the project.

Step-by-Step Guide to Selecting the Ideal Concrete Protection Liner

The first step in choosing the right concrete protection liner is assessing the project needs. Determine the specific challenges your structure will face. Consider factors like chemical exposure, weather conditions, and mechanical stress. Understanding these requirements helps you narrow down the options to liners that can handle your project's unique conditions.

Next, evaluate the performance metrics of different liners. Look at their chemical resistance, durability, flexibility, and installation ease. This step involves comparing various products and their specifications. It’s crucial to select a liner that excels in the areas most important to your project. Durability ensures long-term protection, while flexibility might be vital for complex shapes and installations.

Consulting with experts and manufacturers can provide valuable insights. These professionals have extensive knowledge and can recommend the best liners based on your specific needs. Their experience can help you avoid common pitfalls and ensure you choose a liner that will perform well over time. Lastly, reviewing case studies and successful projects gives you a practical idea of how different liners perform in real-world scenarios. This step helps confirm that the liner you choose has a proven track record in similar applications.

Common Mistakes to Avoid in Choosing Concrete Protection Liners

One common mistake is overlooking environmental factors. It's essential to understand the specific conditions your liner will face. Ignoring factors like temperature extremes, UV exposure, and chemical interactions can lead to premature liner failure. Always consider the full range of environmental conditions to ensure the chosen liner will withstand them.

Ignoring long-term maintenance requirements is another critical error. Some liners may require minimal upkeep, while others could need frequent inspections and repairs. Failing to account for these needs can result in higher maintenance costs and reduced liner lifespan. Choose a liner that balances performance with reasonable maintenance demands.

Choosing based solely on upfront costs can be misleading. While it might be tempting to go for the cheapest option, this can lead to poor performance and higher costs in the long run. A more expensive, higher-quality liner might offer better durability, reducing the need for replacements and repairs. Finally, failing to consult with experienced professionals can lead to uninformed decisions. Their expertise can guide you in selecting the best liner for your project, avoiding costly mistakes.

Conclusion

Selecting the right concrete protection liner is crucial for the longevity and safety of your infrastructure projects. By understanding the different types of liners available and considering essential factors like project requirements, chemical resistance, and long-term costs, you can make an informed decision. Innovative materials now offer superior performance and durability, making them a worthwhile investment for many applications.

Avoiding common mistakes, such as overlooking environmental factors and relying solely on upfront costs, will further ensure that your chosen liner performs effectively over time. Consulting with experts can provide additional assurance that you’re making the best choice for your specific needs.

For high-quality, innovative concrete protection liners and expert advice, you can trust Engineered Containment. We specialize in creating exceptional, leak-free containment systems that meet even the most demanding environmental and infrastructure protection requirements. Get in touch with us today to discover how we can help safeguard your projects.