Protecting Concrete in California: HDPE Liners Are the Best

Best Concrete Protection in CA: HDPE Liners vs. Epoxy

Concrete structures in California face many challenges. The state’s climate is diverse, with hot summers, cooler winters, and occasional earthquakes. These conditions can quickly deteriorate concrete, leading to costly repairs and safety hazards. Finding the right solution to protect these structures is crucial.

Traditional protective coatings like epoxy have been widely used, but they often fall short in these demanding environments. Epoxy coatings can crack under the stress of temperature changes or seismic activity, leaving the concrete vulnerable to damage and corrosion. This is where HDPE (High-Density Polyethylene) liners come into play.

HDPE liners offer a flexible and durable solution for concrete protection. Unlike epoxy, they can adapt to the expansion and contraction of concrete, as well as provide a strong barrier against chemicals and moisture. This makes them a superior choice for extending the lifecycle of concrete structures.

California's Unique Climate Challenges

California's diverse climate poses significant challenges for concrete structures. Summers can reach scorching temperatures (well over 100!), while winters bring cooler, sometimes frosty conditions. The constant fluctuation in temperatures causes concrete to expand and contract. Over time, this natural movement can create cracks and weaken the structure.

Seismic activity is another concern. California is known for its frequent earthquakes, ranging from minor tremors to significant quakes. These seismic events put additional stress on concrete, often leading to structural damage. Traditional protective methods like epoxy coatings struggle to cope with these dynamic forces.

In addition, coastal areas face the relentless assault of saltwater and moisture. Salt can be particularly damaging, causing corrosion and weakening the concrete. Constant exposure to these harsh conditions means that any protective solution must be robust and resilient. HDPE concrete embedment liners are uniquely suited to meet these challenges, offering a level of protection that epoxy coatings simply can't match.

How HDPE Concrete Liners Outperform Epoxy Coatings

When it comes to flexibility, HDPE liners clearly outperform epoxy coatings. HDPE liners are designed to move with the concrete, expanding and contracting without cracking. This is a game-changer in environments like California, where temperature fluctuations and seismic activity are common. Epoxy coatings, on the other hand, are rigid. They tend to crack under stress, leaving the concrete exposed to further damage.

Another advantage of plastic CPL liners is their chemical resistance. They form a strong barrier against harmful substances like saltwater and industrial chemicals. This protective layer helps maintain the integrity of the concrete. Epoxy coatings can provide some chemical resistance, but their performance degrades over time. Chemicals can eventually penetrate the epoxy layer, leading to erosion and corrosion of the concrete.

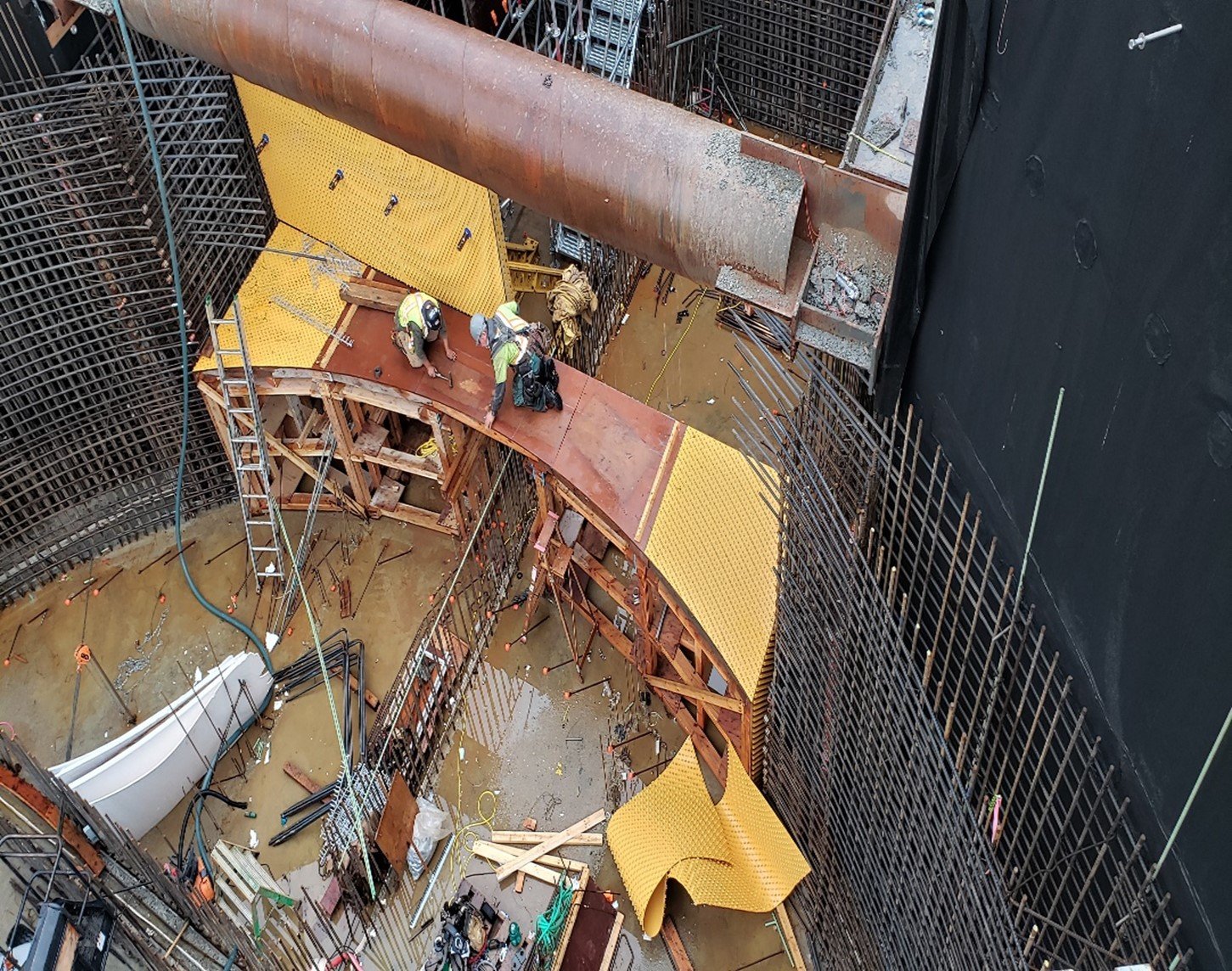

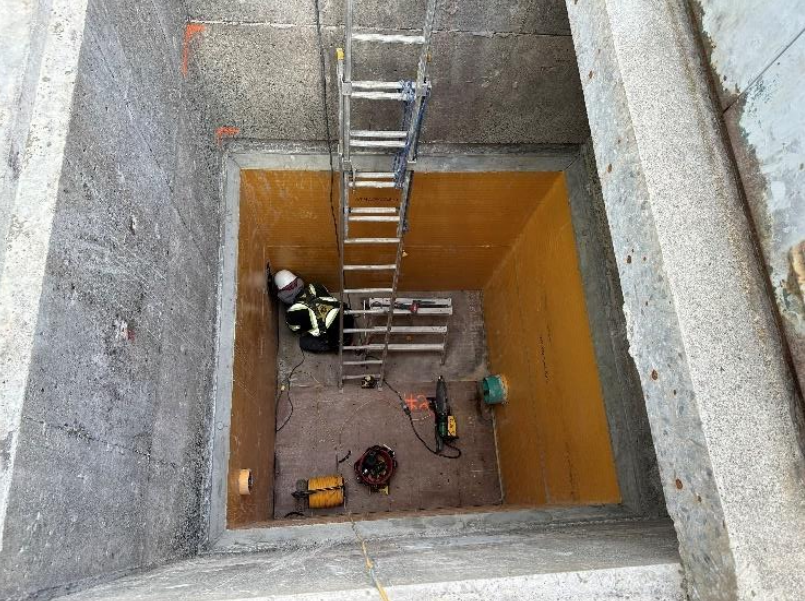

Installing HDPE liners is also more straightforward than applying epoxy coatings. The liners are pre-fabricated to fit specific shapes, making the installation process quicker and less labour-intensive. Epoxy coatings require a clean, dry surface for proper adhesion and a longer curing time, which can delay projects. Overall, HDPE liners provide superior performance and reliability, making them the better choice for protecting concrete structures in California.

Key Benefits of Using EmbededConcrete Geomembrane Liners (CPL)

Concrete geomembrane liners offer numerous benefits that make them the top choice for protecting concrete structures. One of the most significant advantages is their durability. HDPE liners can withstand harsh environmental conditions, including extreme temperatures and seismic activity, without deteriorating. This longevity reduces the need for frequent repairs or replacements, saving both time and money.

Another key benefit is their chemical resistance. HDPE liners form an effective barrier against corrosive substances like saltwater and industrial chemicals. This feature is especially important for coastal and industrial areas in California where exposure to these elements is common. By preventing chemicals from reaching the concrete, HDPE liners help maintain structural integrity for longer periods.

Ease of installation and maintenance is another major advantage. HDPE liners are designed to fit specific shapes and sizes, which simplifies the installation process. They require less prep work compared to epoxy coatings, which need a clean and dry surface. Once installed, HDPE liners are low maintenance, further reducing long-term costs and effort. These benefits make HDPE liners a practical and efficient choice for concrete protection.

Choosing the Right Protection for Your Concrete

Selecting the right protection for your concrete involves considering various factors like environmental conditions, cost, and long-term benefits. In California, where the climate can be tough on concrete structures, HDPE liners stand out as the ideal solution. They offer flexibility, chemical resistance, and durability, which are crucial for maintaining concrete strength and longevity.

Epoxy coatings might seem like a quick fix, but they come with limitations. Their rigid nature makes them prone to cracking under stress, and their chemical resistance diminishes over time. While they may be suitable for less demanding environments, they often fail to provide adequate protection in challenging conditions like those in California.

HDPE liners, on the other hand, address these concerns effectively. Their ability to expand and contract with the concrete prevents cracks and damage. They also offer superior resistance to chemicals and moisture, ensuring the concrete remains protected. When considering long-term costs, HDPE liners prove to be more cost-effective due to their durability and low maintenance needs. For those looking to protect concrete structures in California, embedded HDPE geomembrane liners are clearly the best choice.

Protecting concrete structures in California requires a solution that can withstand the state’s unique environmental challenges. HDPE liners offer the durability, flexibility, and chemical resistance needed to protect concrete from temperature fluctuations, seismic activity, and corrosive elements. They outperform traditional epoxy coatings, which can crack and wear out over time, leading to costly repairs and replacements.

Choosing HDPE liners means investing in long-term protection. Their ease of installation and low maintenance requirements make them a practical and efficient option. By keeping your concrete structures intact and resilient, HDPE liners help you avoid the frequent repairs and high costs associated with other protective coatings.

Embedded Concrete Geomembrane Liner Options

Current CPL Product Lines Available:

AGRU Ultragrip Concrete Protective Liner, Solmax Studliner (formerly called GSE Studliner).

Discontinued CPL Product Lines No Longer Available:

(If these products are on an old specification, they must be updated, as the manufacturers have discontinued their production on a global scale):

KST Holland Concrete Lining (T-Grip), Ameron Sheet Liner (T-Lock)

Ready to safeguard your concrete investments with the best concrete protection available? Contact Engineered Containment today to learn more about how our HDPE liners can provide your structures' durable, long-lasting protection. Our team is here to help you choose the right solution tailored to your specific requirements. Reach out to us now for expert advice and top-quality containment systems.

Start the discussion today by calling us at 1-877-736-0047 or requesting a quote here!