Choosing the Right Concrete Protection: HDPE Liners vs. Epoxy in Miami

Miami's unique climate poses significant challenges for maintaining concrete structures. The city experiences high humidity, intense heat, and frequent rainfall, all of which can degrade concrete over time. These environmental factors lead to issues such as cracking, spalling, and chemical damage, making it crucial to protect concrete assets effectively. Selecting the right type of coating can greatly extend the lifespan and ensure the strength of concrete structures.

HDPE liners (High-Density Polyethylene) and epoxy coatings are two leading solutions for protecting concrete. While both offer benefits, their performance differs significantly based on environmental conditions and specific application needs. In the moisture-rich, hot environment of Miami, choosing the right protection method can mean the difference between a structurally sound asset and one that faces constant repair and maintenance issues.

Understanding Miami's Climate Challenges

Miami's climate presents a unique set of challenges for concrete structures. The city's high humidity levels, combined with scorching temperatures, create an environment where moisture easily seeps into concrete. This trapped moisture can lead to structural damage, such as cracking and spalling, compromising the integrity of concrete over time. The frequent cycle of heavy rains followed by intense sunshine exacerbates these issues, leading to more rapid degradation.

Moreover, Miami is prone to saltwater exposure due to its coastal location. Saltwater can cause severe damage to concrete, leading to corrosion of the reinforcing steel within. This results in weakened structures that require constant maintenance and repair. Protecting concrete in an environment with such harsh conditions necessitates a solution that can withstand both moisture and salt exposure while providing long-term durability.

The constant threat of hurricanes and tropical storms in Miami adds another layer of complexity. These extreme weather events can cause significant damage to unprotected concrete, leading to high repair costs and downtime. Therefore, selecting the right protective coating is essential to ensure the structural longevity and resilience needed to face Miami's challenging climate.

Advantages of HDPE Liners in Miami's Environment

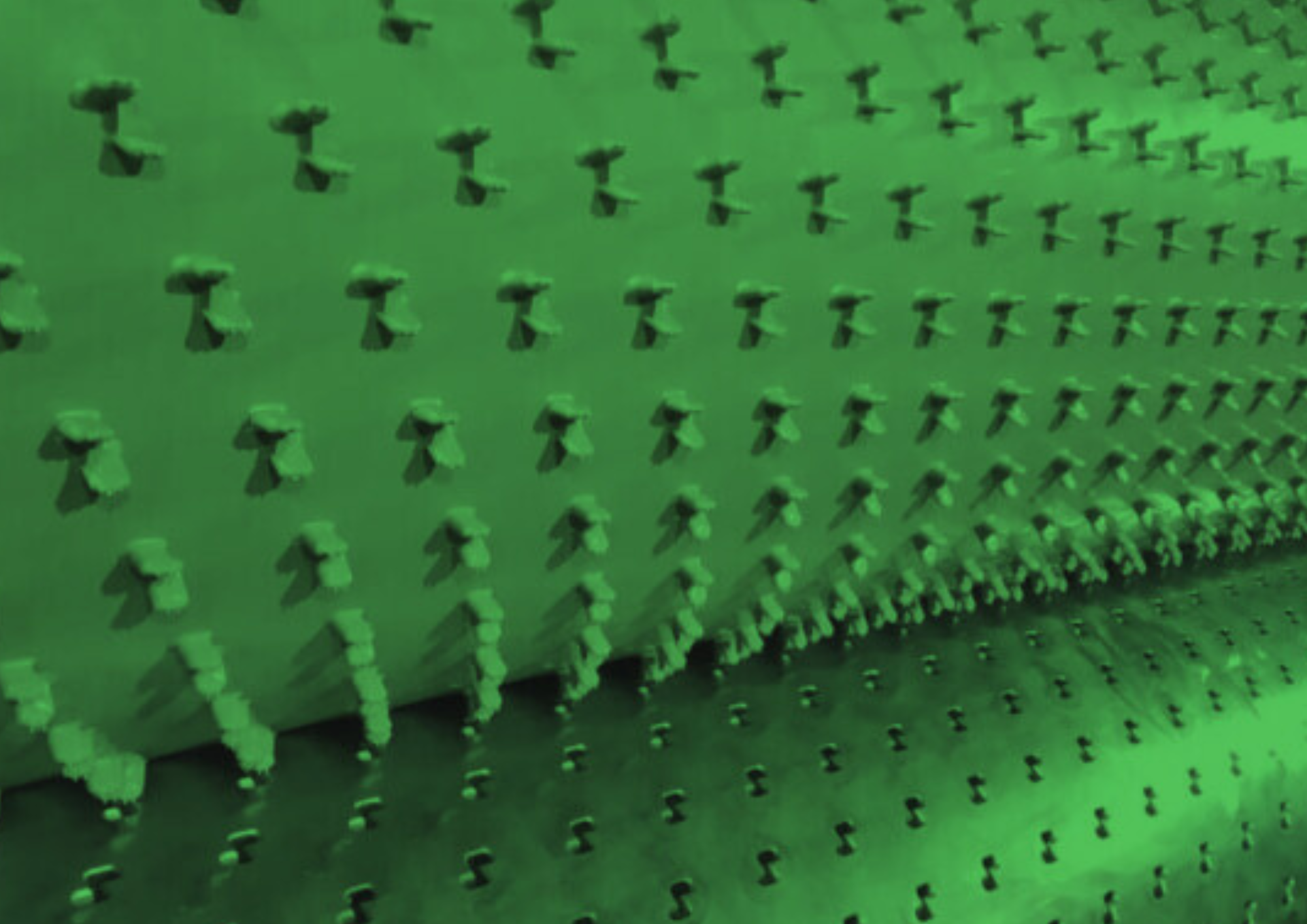

HDPE liners offer several advantages that make them well-suited for protecting concrete in Miami's environment. One of the primary benefits is their exceptional resistance to moisture. HDPE liners create an impermeable barrier that prevents water from penetrating the concrete, reducing the risk of moisture-related damage such as cracks and spalling. This is especially crucial in Miami, where humidity and frequent rains are a daily reality.

Another significant advantage is HDPE's resistance to saltwater. As a coastal city, Miami's concrete structures are often exposed to salt, which can be corrosive. HDPE liners are highly resistant to chemical reactions, including those caused by salt. This makes HDPE an excellent choice for protecting structures near the coastline, piers, and other areas prone to salt exposure.

HDPE liners are flexible and durable, able to withstand the pressures of extreme weather events like hurricanes and tropical storms. Unlike some coatings that can crack or peel under pressure, HDPE liners maintain their integrity, ensuring continuous protection. This ability to withstand harsh conditions without degrading or delaminating makes HDPE liners a reliable choice for long-term concrete protection in Miami.

HDPE concrete liners require minimal maintenance. Their durability and resistance to environmental factors mean they do not need frequent reapplication or repairs, translating into cost savings over time. This reliability, combined with their protective qualities, makes HDPE liners an optimal solution for facing Miami's tough climate challenges.

Comparing HDPE Liners and Epoxy Coatings

When it comes to concrete protection, both HDPE liners and epoxy coatings have their benefits. However, a closer look reveals some significant differences, especially in a challenging environment like Miami's.

1. Flexibility and Durability:

HDPE liners are known for their flexibility, which allows them to expand and contract with the concrete. This flexibility ensures that the liner does not crack or peel, even under extreme conditions. Epoxy coatings, while durable, can become brittle over time, making them more prone to cracking under pressure.

2. Resistance to Chemicals:

Both HDPE liners and epoxy coatings offer good chemical resistance, but HDPE liners excel in environments with high saltwater exposure. This makes HDPE liners especially suitable for coastal areas like Miami, where salt can cause significant damage to unprotected concrete.

3. Installation and Maintenance:

Installing HDPE liners is generally quicker and requires less surface preparation than epoxy coatings. Epoxy coatings often need multiple layers and careful application to ensure complete coverage. Additionally, HDPE liners require less frequent maintenance, reducing long-term upkeep costs. HDPE liners are either cast into the concrete at the precast facility prior to arriving on-site or clad to the form work for cast-in-place/in situ concrete pours.

4. Long-Term Performance:

Over the long term, HDPE liners outperform epoxy coatings in harsh climates and are intended to last the lifetime of the structure without the need for re-application. Epoxy coatings may need regular re-application and repairs, leading to higher maintenance costs over time.

Cost and Environmental Benefits of HDPE Liners

Choosing the right concrete protection method also means considering long-term costs and environmental impact. HDPE liners provide significant cost savings and eco-friendly benefits that make them an excellent choice for concrete protection in Miami.

Cost Savings:

HDPE liners generally have a longer lifespan than epoxy coatings, leading to fewer replacements and repairs over time. Their durability in harsh conditions reduces the need for frequent maintenance, translating to lower overall costs. While the initial installation of HDPE liners might be slightly higher, the reduced need for reapplications and repairs results in substantial long-term savings.

Environmental Benefits:

HDPE liners are also environmentally friendly. They are highly recyclable, which means that construction waste and manufacturing waste can be re-purposed, reducing waste. The production process for HDPE liners involves fewer resources and results in less pollution compared to some other protective methods. Additionally, because HDPE liners require less maintenance, there is a reduced need for harmful cleaning agents, further minimizing their environmental impact.

Durability and Longevity:

The durability of HDPE liners contributes to environmental benefits by reducing the frequency of replacements and the associated waste. Their ability to withstand environmental stressors means fewer materials are needed over time, supporting sustainable construction practices. Engineered Containment focuses on utilizing these concrete liners for a 100 year design service life!

HDPE liners offer excellent long-term cost efficiency and are aligned with environmentally conscious construction practices. Their durability and recyclability make them a smart choice for protecting concrete in Miami while also considering the environment.

Miami, Florida

United States of America

Protecting concrete structures in Miami's harsh climate requires selecting the right coating solution. The extreme weather conditions, high humidity, and saltwater exposure present unique challenges that demand robust protection. HDPE liners stand out as an exceptional option, offering flexibility, superior chemical resistance, and long-term durability.

Compared to epoxy coatings, HDPE liners provide significant advantages in terms of installation ease, maintenance, and environmental impact. Their ability to withstand Miami's challenging environment while reducing overall costs and promoting sustainability makes them an intelligent choice for any concrete protection needs.

For reliable and sustainable concrete protection in Miami, consider the benefits of HDPE liners. Contact Engineered Containment today to learn how our HDPE liners can help safeguard your concrete structures effectively and efficiently.