Comparing HDPE Liners and Epoxy for California Concrete Safety

Concrete structures in California face numerous safety challenges. The state’s climate ranges from hot, dry summers to wet, cool winters, causing concrete to expand and contract. This constant movement can lead to cracks and weaknesses, compromising the safety and integrity of buildings, roads, and bridges. On top of this, California experiences frequent seismic activity, which shakes and stresses concrete structures, adding another layer of risk.

Choosing the right protective coating for concrete is crucial to ensure long-term safety and durability. Epoxy coatings have been a popular choice, providing a hard, protective surface. However, they come with limitations, especially in California’s demanding environment. Cracking, reduced chemical resistance, and challenging installation processes can all undermine their effectiveness over time.

HDPE (High-Density Polyethylene) liners emerge as a superior alternative. They offer flexibility, excellent chemical resistance, and ease of installation, making them well-suited to California’s unique challenges. In this article, we will delve into the safety concerns for concrete in California, compare HDPE liners with epoxy coatings, and highlight how HDPE liners offer long-term benefits. By understanding these factors, you can make an informed decision to enhance the safety and longevity of concrete structures.

Understanding the Safety Concerns for Concrete in California

Concrete structures in California endure unique and severe safety challenges. Temperature changes are a major concern. Summers can be extremely hot, causing concrete to expand. Winters can be cool and wet, causing it to contract. This constant movement leads to small cracks that can grow over time. These cracks not only weaken the concrete, but they also allow water and other harmful substances to penetrate, causing further damage.

Earthquakes are another significant issue. California is located on several major fault lines, making it prone to seismic activity. Even small tremors can cause concrete to crack and break. Larger earthquakes can lead to catastrophic failures of concrete structures. This makes it essential to choose a protective coating that can handle the stress and movement caused by seismic activity.

Additionally, coastal areas of California face the problem of salt air. Salt can corrode the concrete and any metal reinforcements inside. This is especially problematic for structures like bridges and buildings near the ocean. When salt gets into the cracks and pores of the concrete, it accelerates deterioration, compromising structural safety much faster than in non-coastal areas.

Key Differences Between HDPE Liners and Epoxy Coatings

Understanding the differences between HDPE liners and epoxy coatings helps in choosing the right solution for concrete protection. Here are some key aspects:

Flexibility: HDPE liners are more flexible than epoxy coatings. This means they can move with the concrete as it expands and contracts, reducing the risk of cracks. Epoxy, being more rigid, is prone to cracking under similar conditions.

Chemical Resistance: HDPE liners offer superior chemical resistance. They create a robust barrier against a variety of chemicals, including salt and moisture. Epoxy coatings also offer chemical resistance, but not to the same extent as HDPE liners, particularly in harsh environments like coastal areas.

Maintenance: HDPE liners require minimal maintenance once installed. They are durable and long-lasting, reducing the need for frequent repairs. On the other hand, epoxy coatings may need more regular upkeep and repairs, increasing long-term costs.

Overall, HDPE liners provide better performance in terms of flexibility, chemical resistance, ease of installation, and maintenance, making them more suitable for the tough environmental conditions in California.

Assessing the Long-Term Benefits of HDPE Liners

HDPE liners offer several long-term benefits that make them a superior choice for protecting concrete structures in California. One of the most significant advantages is their durability. HDPE liners are designed to withstand extreme conditions, including temperature changes, chemical exposure, and physical stress. This durability ensures that the liner, and therefore the concrete, remains intact and effective for many years.

Another major benefit is the reduced need for maintenance. Because HDPE liners are so durable, they require less frequent inspections and repairs compared to other coatings. This can lead to significant cost savings over the lifespan of the concrete structure. In comparison, epoxy coatings might need regular upkeep and periodic reapplications, which can become costly and time-consuming.

HDPE liners also provide strong protection against environmental damage. They resist chemical and salt intrusion, which is particularly important in coastal areas of Southern California. By preventing these harmful substances from penetrating the concrete, HDPE liners help extend the life of the structure. This is especially beneficial for infrastructure like bridges, seawalls, and buildings near the ocean, where exposure to salt air can rapidly accelerate deterioration.

Selecting the Right Solution for Your Concrete Safety Needs

Choosing the right solution for concrete safety involves evaluating several key factors. First, consider the specific environmental hazards your concrete structure will face. In Southern California, this often means accounting for high temperatures, seismic activity, and salt exposure. HDPE liners are well-suited to handle these challenges due to their flexibility, chemical resistance, and durability.

Next, think about the long-term costs and maintenance requirements. While initial costs for HDPE liners might be higher than epoxy coatings, the reduced need for maintenance and longer lifespan can make them more cost-effective in the long run. The ease of installation is another factor to consider. HDPE liners typically offer a simpler and faster installation process compared to the meticulous preparation required for epoxy coatings.

Finally, prioritize the overall protection and longevity of your concrete structure. HDPE liners provide comprehensive protection against a range of environmental threats, ensuring the concrete remains strong and safe for years to come. By focusing on these key considerations, you can make an informed decision that best meets your concrete safety needs and maximizes the lifespan of your structure.

Protecting concrete structures in Southern California presents unique challenges, from extreme temperatures to seismic activity and salt air exposure. While epoxy coatings have been a traditional choice, they come with limitations that make them less effective in such demanding conditions. HDPE liners, with their superior flexibility, chemical resistance, and ease of installation, emerge as a more reliable option for ensuring the safety and longevity of concrete structures.

The long-term benefits of HDPE liners, including reduced maintenance needs and strong environmental protection, make them a cost-effective solution. By choosing HDPE liners, you invest in the durability and safety of your concrete, ensuring it can withstand the harsh conditions of Southern California. This not only prolongs the life of your infrastructure but also provides peace of mind knowing your structures are well-protected.

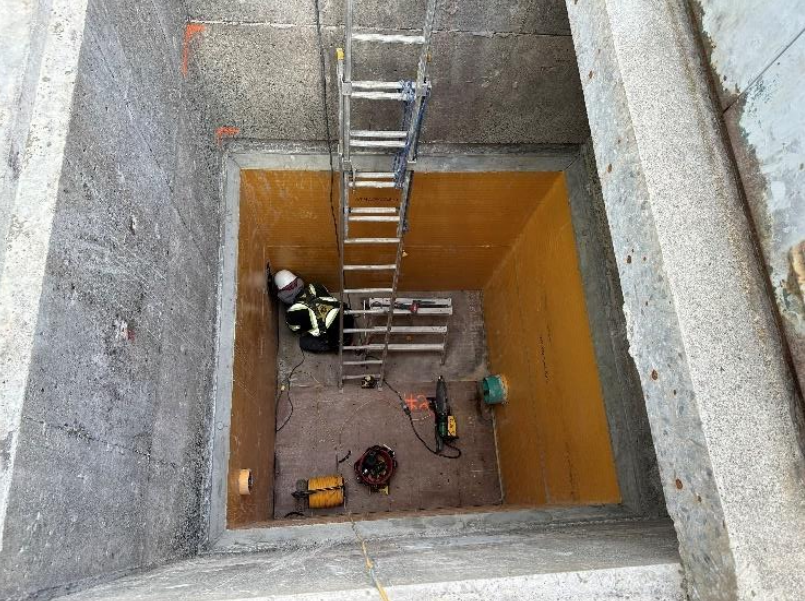

For those looking to safeguard their concrete structures in Southern California, concrete protective liners (lined precast concrete and liner for cast-in-place concrete) offer the best protection. At Engineered Containment, we specialize in combining geosynthetics (geomembrane liners) with value engineering to create exceptional containment systems. Contact Engineered Containment today to learn more about how our HDPE liners can provide the optimal protection your concrete structures need. We're here to help you make the best choice for your concrete safety requirements.